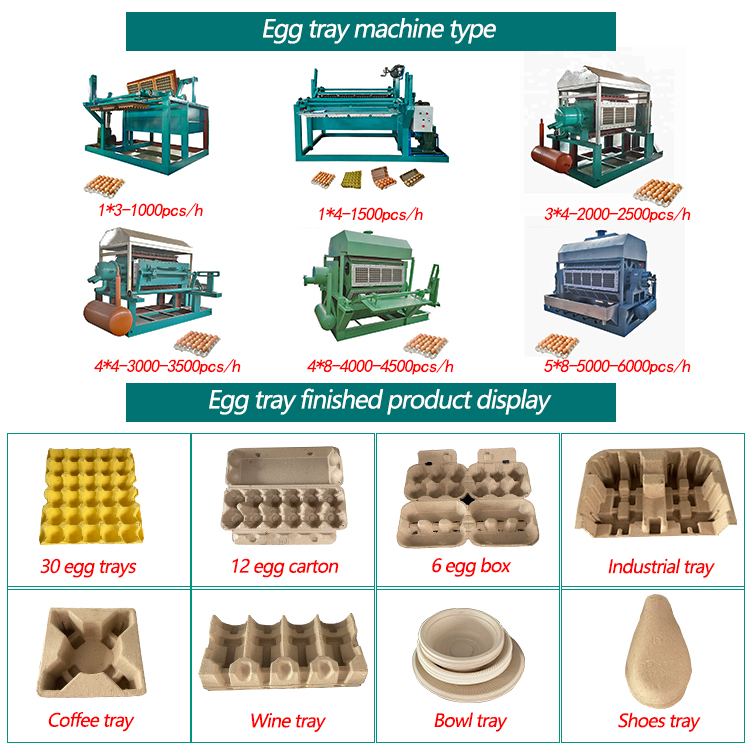

1. Umugqa wokukhiqiza we-Pulp Moulding waziwa ngokuthi umugqa wethreyi yamaqanda okusetshenziswa kakhulu ekukhiqizeni ithreyi yamaqanda.

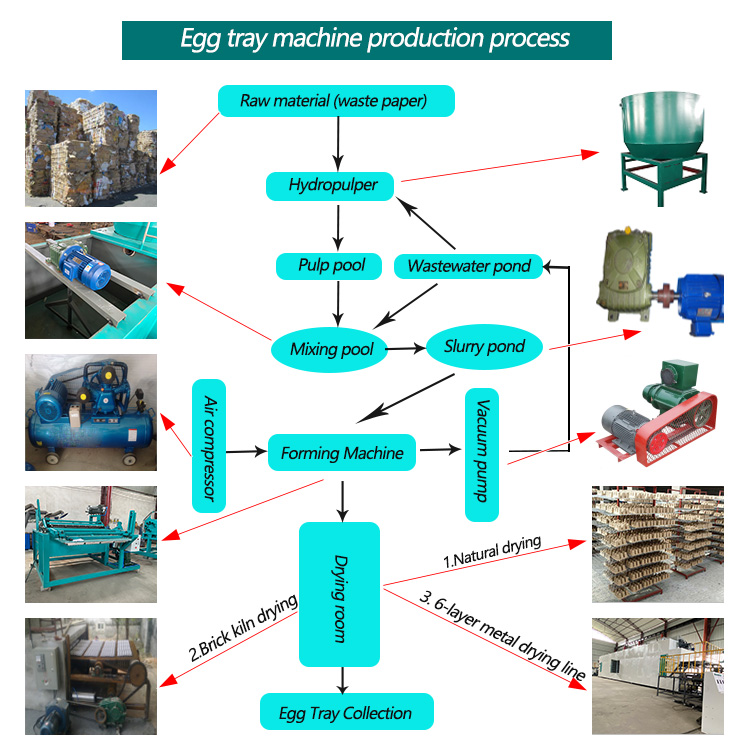

2. Umugqa wokukhiqiza i-Pulp Moulding, osebenzisa iphepha elingcolile, ikhadibhodi, izinto ezisele zomshini wokugaya iphepha, nge-hydraulic pulper, ingxube eyenza i-pulp ethile ebanzi, kanye ne-pulp imuncwa yi-vacuum yokubumba insimbi ekhethekile ukuze ibe imikhiqizo emanzi, ngokuyimisa, nangokuyibumba ukuze ibe imikhiqizo eqediwe.

3. Ukucubungula umugqa wokubumba ama-pulp kusebenzisa amanzi asetshenziswe kabusha futhi akuholeli ekungcoleni kwamanzi noma komoya. Imikhiqizo yokupakisha eqediwe ingaphinde isetshenziswe ngemuva kokusetshenziswa ekugcinweni, ekuthuthweni nasekuthengisweni. Ngemva kokusikwa, kulula ukubola njengephepha, noma ngabe ilahlwe endaweni yemvelo.

4. Imigqa yokukhiqiza i-pulp molding ezenzakalelayo ingaba ukukhiqizwa okukhulu kwesitsha sokudla esihlukahlukene, ithreyi lamaqanda, amabhokisi esidlo sasemini njalo njalo.

| Imodeli Yomshini | 1*3/1*4 | 3*4/4*4 | 4*8/5*8 | 5*12/6*8 |

| Isivuno (p/h) | 1000-1500 | 2500-3000 | 4000-6000 | 6000-7000 |

| Iphepha Lokuchitha (kg/h) | 80-120 | 160-240 | 320-400 | 480-560 |

| Amanzi (kg/h) | 160-240 | 320-480 | 600-750 | 900-1050 |

| Ugesi (kw/h) | 36-37 | 58-78 | 80-85 | 90-100 |

| Indawo Yokusebenzela | 45-80 | 80-100 | 100-140 | 180-250 |

| Indawo Yokomisa | Asikho isidingo | 216 | 216-238 | 260-300 |

Idrayivu yemoto ye-servo enembile kakhulu, ukusebenza kahle okuphezulu kanye nomugqa wokomisa owonga amandla.

1, Sebenzisa injini ye-servo yokunciphisa ngokunemba ukwakha nokudlulisa ukuqinisekisa ukusebenza okusheshayo nokusebenza okusheshayo.

2, Sebenzisa i-absolute encoder ukuze uthole ukulungiswa okunembile.

3, Ukusetshenziswa kwesakhiwo sendandatho esiqinile nesiguquguqukayo sethusi kufaneleka kakhulu enkambisweni yokukhipha amanzi kumkhiqizo.

4, Ukusetshenziswa kwesakhiwo somshini ukuqinisekisa ukuthi isikhunta sivala ngokulinganayo kuzo zombili izinhlangothi.

5, Umthamo omkhulu; Okuqukethwe kwamanzi kuphansi; Yonga izindleko zokomisa.

1. Uhlelo lokudonsa amanzi

2. Uhlelo lokwakha

3. Uhlelo lokomisa

(3) Umugqa omusha wokomisa onezingqimba eziningi: Umugqa wokomisa wensimbi onezingqimba eziyisithupha ungonga amandla angaphezu kuka-30%

4. Ukupakisha okuwusizo komkhiqizo oqediwe

(2) Umthengisi

(3) Umthuthi wokudlulisa

-

Umshini wokwenza ithreyi yeqanda lephepha le-Bamboo Young Bamboo ...

-

Ibhokisi Lebhokisi Lebhokisi Le-Waste Paper Recycling Egg Carton Tray M ...

-

Umshini wokwenza ithreyi yamaqanda i-YB-1*3 1000pcs/h we-bu...

-

Umugqa wokukhiqiza wethreyi yeqanda lephepha elizenzakalelayo / ...

-

Umshini Wokwenza I-Egg Tray Pulp Molding We-Small ...

-

Iphepha lokulahlwa elizenzakalelayo le-pulp egg tray yokwenza i-mach ...